1325 1530 Tsis-Hlau Khoom Laser Tej Tshuab

APPLICATION

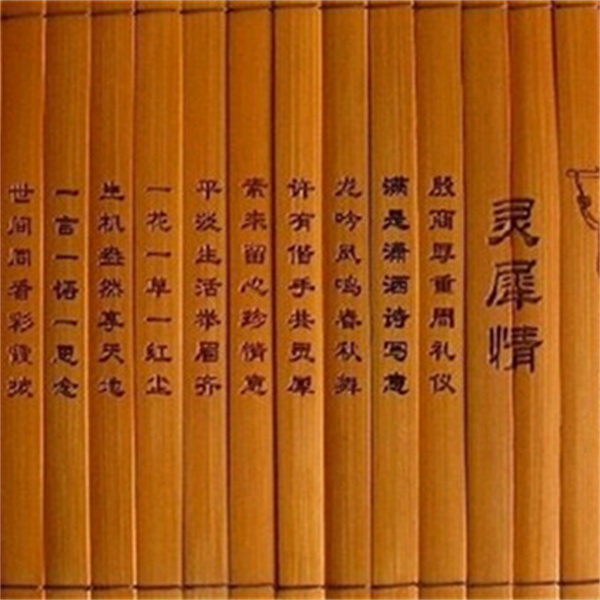

Co2 laser txiavyog thiab engraveryog professionalraunon-hlau txiav thiab engraving, haum rau acrylic, ob chav xim board, tawv, ntaub, ntawv, ntoo ntim lub thawv, xyoob, plhaub, kaus ntxhw, roj hmab, marble thiab hais txog.

Co2 laser txiavyog thiab engraveryog professionalraunon-hlau txiav thiab engraving, haum rau acrylic, ob chav xim board, tawv, ntaub, ntawv, ntoo ntim lub thawv, xyoob, plhaub, kaus ntxhw, roj hmab, marble thiab hais txog.

| Khoom siv | Kev kos duab | Txiav | Khoom siv | Kev kos duab | Txiav |

| Acrylic | √ | √ | MDF | √ | √ |

| Ob chav xim Board | √ | √ | Roj hmab | √ | √ |

| Ntuj Ntoo | √ | √ | Plywood | √ | √ |

| Npuag | √ | √ | Yas | √ | √ |

| Xyoob | √ | √ | Tawv | √ | √ |

| Matte Board | √ | √ | Ntawv | √ | √ |

| Mylar | √ | √ | Fiber ntauiav | √ | √ |

| Xovxwm board | √ | √ | Ceramic | √ | × |

| Granite | √ | × | Marble | √ | × |

| iav | √ | × | Pob zeb | √ | × |

| Rautshwj xeebkhoom, thov paub meej ua ntej | |||||

PARAMETER

| Ua Haujlwm Loj: 1300 * 2500mm 1500 * 3000mm / 2000 * 3000mm | Lub cev muaj zog: 100W / 130W / 150W / 300W |

| Laser hom: CO2 kaw-tawm iav raj | Laser Tube Hom: Reci / Efr / Yongli / Xinrui |

| Kev xa mus: X axis pob ntsia hlau + Y axis khib | Kev Ua Haujlwm thiab Software: RDC6445G RD ua haujlwm V8 |

| Cooling System: Dej txias | Laser Output Control: 0-100% tsis muaj seem tswj, mos sab hauv 0-100% adjustable |

| Dej Chiller: S & A | Tsav thiab Tsav: Ntshiab Servo |

| Engraving ceev: 0-1200mm / s | Yam tsawg kawg Tsab Ntawv Loj: Lus Askiv: 1mm |

| Reposition Qhov tseeb: ≤ ± 0.05mm | Interface: LCD npo nrog USB interface |

| Kis hom: High-precision Taiwan QAQ khib qhia rail | Ua haujlwm Voltage: AC220V / 50 / 60HZ (yeem 380V lossis 110V) |

| Ua haujlwm ib puag ncig: Kub: 0-45 ° C / humidity: 5% -80% | Txhawb hom: DXF, AI, DST, DWG, BMP, ETC |

NTA

1.Precise guide rails xyuas kom meej thiab tsis muaj kev ua yuam kev. Lub pioneering nruam, ceev nkhaus txiav thiab shortest ua txoj kev optimization txhim kho kev ua hauj lwm efficiency; stabilized tas li tam sim no laser fais fab mov Cheebtsam kom ntev lub neej ntawm lub laser raj.

2. Lub txajua los ntawm 8mm tuab thiab100 hli dav square yeeb nkab, yuav tsis deform, tswj siab precision ntev.

3.Racks thiab gears yog hauv av precisely, hnav-resistant thiab high-precision.

4.Helical iav reduceris 81π(tsis 31π), ntau zoo zoo thiab siab precision.

5.Qhov nws tus kheej-tsim sab sauv qhov cua patent, ua ke nrog kev faib tawm qhov cua, tuaj yeem nqus cov pa khib nyiab pov tseg thiab cov pa taws uas tsim tawm thaum lub sijhawm ua haujlwm loj.

6.Machine txais thoob ntiaj teb DSP thev naus laus zis cais los ntawm kev ua haujlwm hauv computer; USB interface, txhawb U disk, USB, network cable kis hom.

NTAUB NTAWV

Ua hauj lwm txaj:Fine milling txheej txheem rau txhua lub tshuab txaj, xyuas kom meej lub tshuab tiav,guaranteed siab raug.

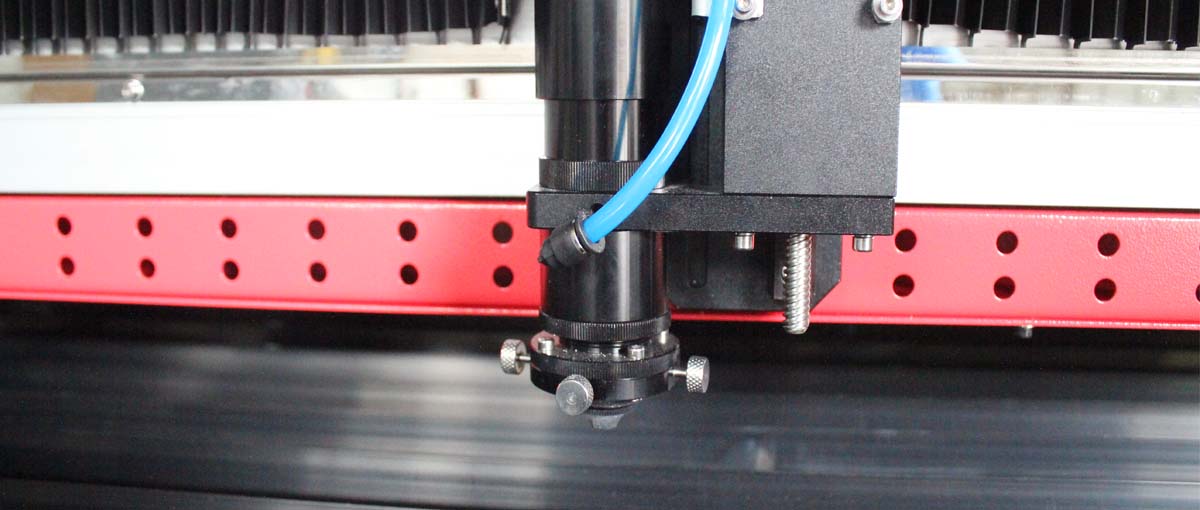

X axis:Nws yog pob ntsia hlau xa mus rau X axis, siab dua precision, zoo heev rau Artware kev lag luam.

Y Axis:Lub Y-axis yog DIN6 precision qib sib tsoo-qib khib, uas muaj qhov siab dua thiab ruaj khov zoo dua li siv txoj siv sib kis.

Test ntaus ntawv: Balancer, collimator thiab lwm yam kev nrhiav kom tau covtshuab txaj,coj railthiabkhib qib,nws yog KEY kauj ruam los xyuas kom meej qhov tseeb tshuab.

Tsis tu ncua Laser Path:Peb siv txoj kev laser tas li ntawm 5 daim iav ntawm lub tshuab no, kom qhov kev ncua deb ntawm lub laser los ntawm lub qhov hluav taws xob laser raj rau cov khoom siv yuav nyob twj ywm tsis tu ncua txawm tias lub taub hau laser txav mus qhov twg.

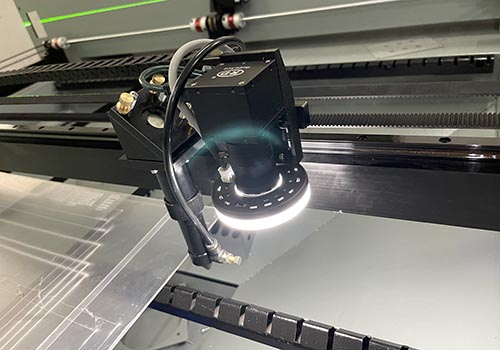

Inbuilt Auto Focus:Kev ua kom pom tseeb tshwj xeeb tuaj yeem kho tau qhov ua kom pom tseeb raws litxawv tuabcov ntaub ntawv, tsis tas yuav hloov lub taub hau, haum rau txhua lub lens.

Qauv

Ua hauj lwm VIDEO

Ua hauj lwm VIDEO

Plaub txiav taub hau

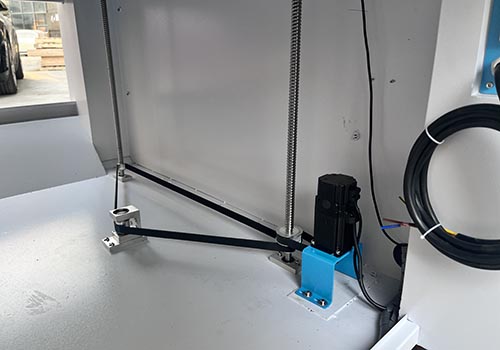

Up thiab down rooj

Rotary

Lub koob yees duab

Tsis siv neeg tsom

Chav hluav taws kub

Qhov taw qhia lub teeb

Lub teeb liab

Kev cob qhia

Peb muab kev cob qhia kev cob qhia pub dawb kom txog thaum cov neeg siv khoom tuaj yeem siv cov khoom siv ib txwm. Cov ntsiab lus tseem ceeb ntawm kev cob qhia yog raws li nram no:

1. Kev paub yooj yim thiab cov ntsiab lus ntawm laser.

2. Laser kev tsim kho, kev ua haujlwm, kev tu thiab tu.

3. Lub hauv paus ntsiab lus ntawm hluav taws xob, kev ua haujlwm ntawm CNC system, kev kuaj xyuas kev txhaum.

4. Laser txiav txheej txheem.

5. Kev ua haujlwm thiab kev tu txhua hnub ntawm cov cuab yeej siv tshuab.

6. Kev kho thiab kev kho qhov muag kho qhov muag system.

7. Kev kawm txog kev nyab xeeb ntawm laser.