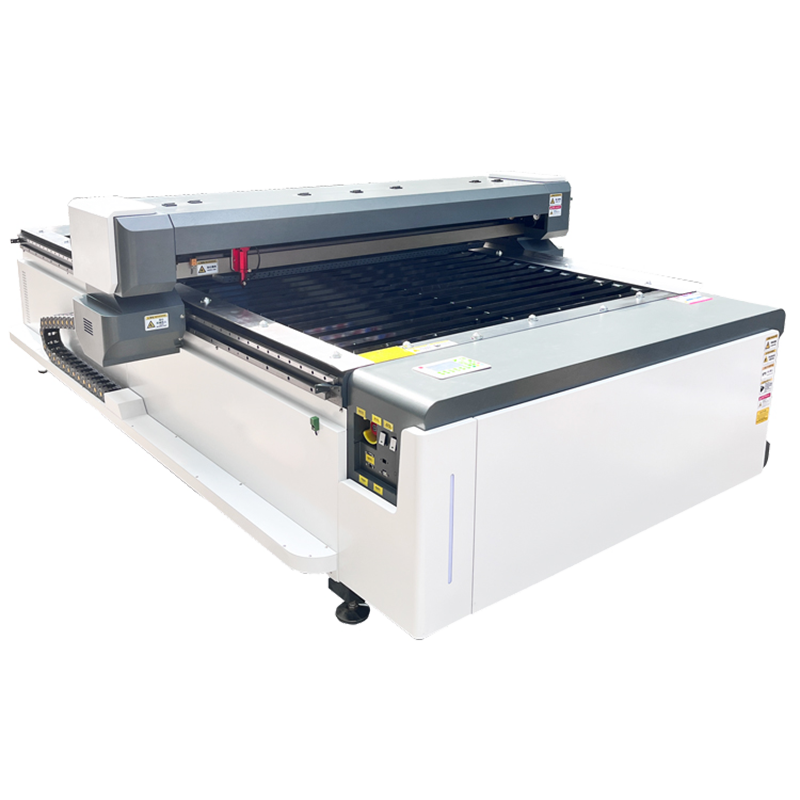

Kub muag Hoobkas 9060 1390 1610 1325 CO2 Laser Engraving Tej Tshuab

Peb vam khom lub zog technical force thiab txuas ntxiv tsim cov thev naus laus zis kom ua tau raws li qhov xav tau ntawm Kub muag Hoobkas 9060 1390 1610 1325 CO2 Laser Engraving Txiav Tshuab, Peb cog lus tias yuav sim peb qhov zoo tshaj plaws los xa koj cov khoom lag luam zoo thiab cov kev pabcuam.

Peb nyob ntawm qhov ruaj khov technical force thiab txuas ntxiv tsim cov thev naus laus zis kom ua tau raws li qhov xav tau ntawmTuam Tshoj CO2 Laser Tej Tshuab thiab Laser Tej Tshuab CO2, Tsis tas li ntawd, peb tau txais kev txhawb nqa los ntawm cov kws tshaj lij thiab cov kws tshaj lij, uas muaj kev txawj ntse loj hauv lawv cov npe. Cov kws tshaj lij no ua haujlwm sib raug zoo nrog ib leeg los muab peb cov neeg siv khoom muaj txiaj ntsig zoo ntawm cov khoom thiab cov kev daws teeb meem.

APPLICATION

| Khoom siv | Kev kos duab | Txiav | Khoom siv | Kev kos duab | Txiav |

| Acrylic | √ | √ | MDF | √ | √ |

| Ob chav xim Board | √ | √ | Roj hmab | √ | √ |

| Ntuj Ntoo | √ | √ | Plywood | √ | √ |

| Npuag | √ | √ | Yas | √ | √ |

| Xyoob | √ | √ | Tawv | √ | √ |

| Matte Board | √ | √ | Ntawv | √ | √ |

| Mylar | √ | √ | Fiber iav | √ | √ |

| Xovxwm board | √ | √ | Ceramic | √ | × |

| Granite | √ | × | Marble | √ | × |

| iav | √ | × | Pob zeb | √ | × |

| Rau cov khoom tshwj xeeb, thov paub meej ua ntej | |||||

PARAMETER

| Ua Haujlwm Loj: 1300 * 2500mm / 1500 * 3000mm | Lub cev muaj zog: 80W / 100W / 130W / 150W / 200W / 300W |

| Laser hom: CO2 kaw-tawm iav raj | Kev khiav hauj lwm System thiab Software: RDC6445G RD ua haujlwm V8 |

| Cooling System: Dej txias | Tsav thiab Tsav: servo |

| Txiav ceev: 0-600mm / s | Engraving ceev: 0-1200mm / s |

| Reposition Qhov tseeb: ≤ ± 0.01mm | Yam tsawg kawg Tsab Ntawv Loj: Lus Askiv: 1mm |

| XY Guiding System: Linear guide rails | Interface: LCD npo nrog USB interface |

NTA

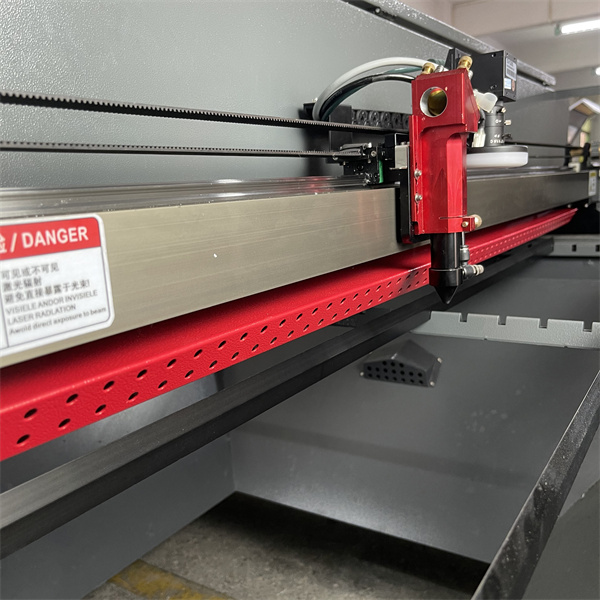

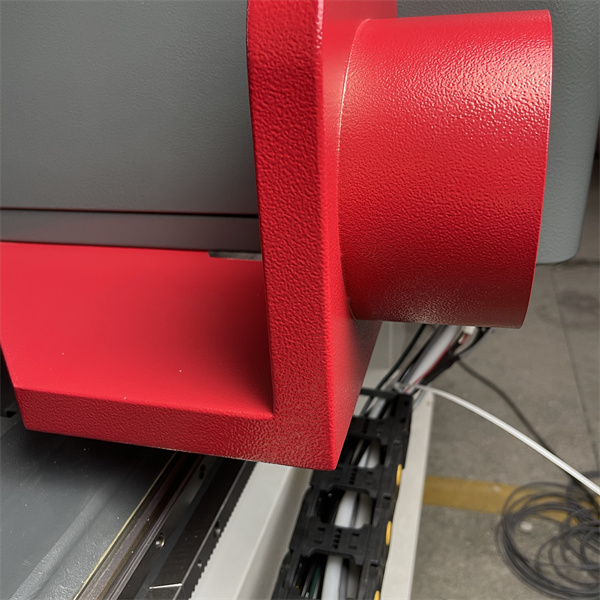

1.Precise guide rails xyuas kom meej thiab tsis muaj kev ua yuam kev. Lub pioneering nruam, ceev nkhaus txiav thiab shortest ua txoj kev optimization txhim kho kev ua hauj lwm efficiency; stabilized tas li tam sim no laser fais fab mov Cheebtsam kom ntev lub neej ntawm lub laser raj.

2.Siv cov qauv duab peb sab ntawm lub txaj sab, tshuab yog ruaj khov dua, thiab siab precision.

3.Bed thiab X-axis beam nrog 6mm steel, tshuab lub cev yog 1.5mm steel, yuav tsis deform, tswj siab precision ntev.

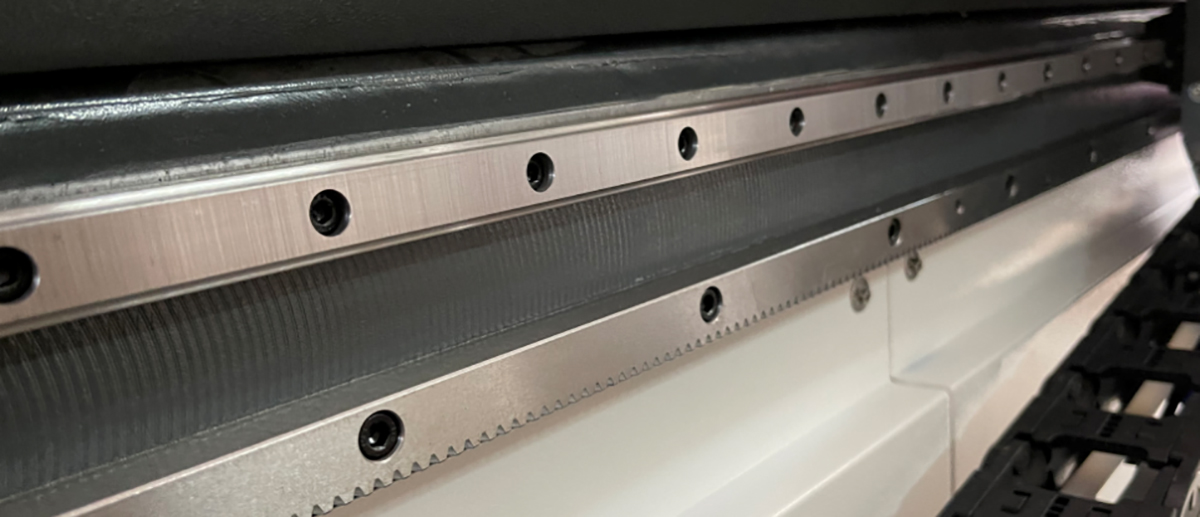

4.Racks thiab gears yog precisely hauv av, hnav-resistant thiab high-precision.

5.Helical iav reducer yog 81π thaum lwm tus siv 31π reducer, zoo dua thiab siab precision.

6.3 theem motors xyuas kom muaj kev kub ceev txiav thiab kev ua haujlwm zoo.

7. ua raws li cov pa taws tso tawm, uas tuaj yeem ua raws li lub taub hau txiav rau cov pa pa tawm

NTAUB NTAWV

Nws txais yuav lub txaj hnyav tsim qauv tsim, uas tau nce mus rau 8 hli tuab hlau thiab ruaj khov zoo dua piv nrog lub tshuab txaj ntawm kev ua lag luam, mus txog qib siab hauv kev lag luam.

Peb qhov kev txhawb nqa tshiab tau ntxiv rau ntawm lub txaj. Tom qab machining chaw zoo milling, cov hniav yog nteg nyob rau hauv cov kev txhawb nqa tuav tsis muaj phau ntawv hloov ntawm qhov raug, txo machining yuam kev, ua rau tag nrho cov qauv txaj tsim ntau leej tshaj lwm yam zoo tib yam tshuab, thiab tsis yooj yim rau deform.

Cov khoom siv kho vajtse, cov khoom siv hlau thiab kev tsheb nqaj hlau thiab cov khoom siv cov yeeb nkab txhawb nqa yog tag nrho ua los ntawm No1 hom txhuas cov khoom, cov khoom siv zog dua thiab hnyav uas yuav tiv thaiv lub tshuab los ntawm deformation, tsis muaj kev vibration, xyuas kom meej ntau dua.

Racks thiab gears yog hauv av precisely, hnav-tiv taus thiab high-precision, qhov chaw uas cov kev taw qhia rail thiab khib ntsia yuav raug nplua-milled los ntawm machining chaw los xyuas kom meej meej flatness

Kev txawj ntse taug qab cov pa pa tawm system, uas tuaj yeem ua raws li lub taub hau txiav rau cov pa pa tawm.

Qauv

Ua hauj lwm VIDEO

Ua hauj lwm VIDEO

Kev cob qhia

Peb muab kev cob qhia kev cob qhia pub dawb kom txog thaum cov neeg siv khoom tuaj yeem siv cov khoom siv ib txwm. Cov ntsiab lus tseem ceeb ntawm kev cob qhia yog raws li nram no:

1. Kev paub yooj yim thiab cov ntsiab lus ntawm laser.

2. Laser kev tsim kho, kev ua haujlwm, kev tu thiab tu.

3. Lub hauv paus ntsiab lus ntawm hluav taws xob, kev ua haujlwm ntawm CNC system, kev kuaj xyuas kev txhaum.

4. Laser txiav txheej txheem.

5. Kev ua haujlwm thiab kev tu txhua hnub ntawm cov cuab yeej siv tshuab.

6. Kev kho thiab kev kho qhov muag kho qhov muag system.

7. Kev kawm txog kev nyab xeeb ntawm laser.

Peb vam khom lub zog technical force thiab txuas ntxiv tsim cov thev naus laus zis kom ua tau raws li qhov xav tau ntawm Kub muag Hoobkas 9060 1390 1610 1325 CO2 Laser Engraving Txiav Tshuab, Peb cog lus tias yuav sim peb qhov zoo tshaj plaws los xa koj cov khoom lag luam zoo thiab cov kev pabcuam.

Kub muag HoobkasTuam Tshoj CO2 Laser Tej Tshuab thiab Laser Tej Tshuab CO2, Tsis tas li ntawd, peb tau txais kev txhawb nqa los ntawm cov kws tshaj lij thiab cov kws tshaj lij, uas muaj kev txawj ntse loj hauv lawv cov npe. Cov kws tshaj lij no ua haujlwm sib raug zoo nrog ib leeg los muab peb cov neeg siv khoom muaj txiaj ntsig zoo ntawm cov khoom thiab cov kev daws teeb meem.