Laser tu thiab pickling yog ob txoj kev sib txawv rau kev kho cov hlau nto.Laser tu yog cov txheej txheem kev kho hlau hlau uas siv lub laser beam tawm los ntawm lub tshuab hluav taws xob laser los tsim lub zog siab kom tshem tawm xeb, strip xim, thiab tshem tawm cov coatings.Pickling yog ib txoj kev kho mob uas siv los tshem tawm xeb, stains, impurities, los yog cov kab mob ntawm cov hlau.

Pickling

Daim ntawv pickling yog ua los ntawm cov ntawv zoo kub-kuav los tiag raws li cov khoom siv raw, thiab cov oxide txheej raug tshem tawm los ntawm chav tsev pickling, trimmed, thiab tiav.Cov khoom nruab nrab nruab nrab ntawm daim hlau, ntawm qhov chaw ntawm kev ua kom lub ntsej muag zoo thiab siv cov kev xav tau, ua rau cov neeg siv kom txo tau tus nqi yuav khoom.

Pickling Ntawv Qhov Zoo

1. Qhov saum npoo zoo yog qhov zoo, vim tias cov nplais hlau oxide raug tshem tawm ntawm lub phaj kub-kuav los tiag, uas txhim kho qhov zoo ntawm cov hlau thiab yooj yim vuam, oiling thiab pleev xim.

2. High dimensional precision, tom qab flattening, lub phaj zoo tuaj yeem hloov mus rau ib qho twg, yog li txo qhov sib txawv ntawm qhov tsis sib xws.

3. Txhim kho qhov chaw tiav thiab txhim kho qhov tsos.

Daim ntawv thov

Nws tuaj yeem hais tau tias daim ntawv pickling yog cov khoom lag luam raug nqi nruab nrab ntawm cov ntawv txias-dov thiab cov ntawv kub-dov.Nws muaj ntau yam kev siv hauv kev lag luam automotive, machinery kev lag luam, lub teeb muaj khoom siv thiab stamping qhov chaw ntawm ntau yam duab, xws li kab teeb, sub-beams, rims, spokes, carriage panels, kiv cua, tshuaj roj drums, welded kav, hluav taws xob. cov txee, laj kab, Hlau ntaiv, thiab lwm yam, muaj kev lag luam dav dav.Hauv qab no peb yuav qhia txog cov txheej txheem txheej txheem ntawm cov txheej txheem pickling.

Pickling Txoj Cai

Pickling yog txheej txheem saum npoo uas siv cov kua qaub kom tshem tawm cov nplai thiab xeb ntawm cov hlau, feem ntau ua ke nrog kev ua yeeb yaj kiab ua ntej.Feem ntau, lub workpiece yog immersed nyob rau hauv ib tug tshuaj tov xws li sulfuric acid kom tshem tawm oxides thiab lwm yam films ntawm cov hlau nto, uas yog pre-kho los yog intermediate kev kho mob ntawm electroplating, enamel, dov thiab lwm yam txheej txheem.Kuj hu ua ntub tu.

Cov txheej txheem pickling feem ntau suav nrog dipping pickling method, spray pickling method thiab acid paste rust remove method.

Cov kua qaub uas siv feem ntau yog sulfuric acid, hydrochloric acid, phosphoric acid, nitric acid, chromic acid, hydrofluoric acid thiab cov kua qaub sib xyaw.

Txheej Txheem Flow

Dai rau ntawm cov hlau → tshuaj degreasing (paj alkaline tshuaj degreasing los yog surfactant degreasing) → dej kub ntxuav → khiav dej ntxuav → thawj kauj ruam ntawm pickling → khiav dej ntxuav → Ob kauj ruam pickling → khiav dej ntxuav → hloov mus rau lwm yam txheej txheem (xws li xws li: tshuaj pleev xim → recycling → khiav dej ntxuav → hardening kho → Ntxuav → Kaw kho → Ntxuav → ziab → tiav).

Tej yam tsis zoo

Iron oxide scale intrusion: Hlau oxide nplai intrusion yog ib qho chaw deg tsim thaum kub dov.Tom qab pickling, nws yog feem ntau nias nyob rau hauv cov duab ntawm cov dots dub thiab strips, nto yog ntxhib, feem ntau muaj tes xav, thiab tshwm sporadically los yog intensively.Nws feem ntau tshwm sim los ntawm cov txheej txheem cua sov tsis zoo, txheej txheem descaling thiab dov txheej txheem ntawm pickling.

Oxygen spot (surface toj roob hauv pes painting): yog hais txog lub dot-zoo li, linear los yog pit-zoo li zoo li sab laug tom qab cov hlau oxide nplai nyob rau saum npoo ntawm cov kub dov hlau yog ntxuav tawm.Lub dov yog nias rau hauv lub matrix, uas yog highlighted tom qab pickling.Nws muaj qee yam cuam tshuam rau qhov tsos, tab sis tsis cuam tshuam rau kev ua haujlwm.

Macular: daj me ntsis tshwm rau ntawm ib feem lossis tag nrho lub rooj tsavxwm nto, uas tsis tuaj yeem npog tom qab oiling, uas cuam tshuam rau qhov zoo thiab zoo ntawm cov khoom.Qhov laj thawj tseem ceeb yog vim li cas qhov kev ua haujlwm saum npoo ntawm cov sawb tsuas yog tawm ntawm lub tank pickling yog siab, cov dej yaug dej tsis huv ntawm cov sawb ib txwm, cov kab tsuag tsuag thiab lub taub dej ntawm lub tank yaug yog thaiv, thiab cov ces kaum tsis sib npaug.

Hauv qab-pickling: Qhov saum npoo ntawm cov sawb hlau muaj cov nplais hlau oxide hauv zos uas tsis huv thiab tsis txaus tshem tawm, thiab cov phaj saum npoo yog grey-dub, nrog cov ntses nplai lossis kab rov tav dej ripples.Nws muaj ib yam dab tsi ua rau cov txheej txheem kua qaub, feem ntau vim tias cov kua qaub concentration tsis txaus, qhov kub thiab txias tsis siab, cov sawb khiav nrawm heev, thiab cov sawb tsis tuaj yeem tso rau hauv cov kua qaub.

Over-pickling: Qhov saum npoo ntawm cov sawb hlau feem ntau yog xim dub lossis xim av xim av, qhia thaiv, flaky dub me ntsis los yog macular, thiab saum npoo ntawm phaj feem ntau ntxhib.Yog vim li cas yog qhov opposite ntawm underpickling.

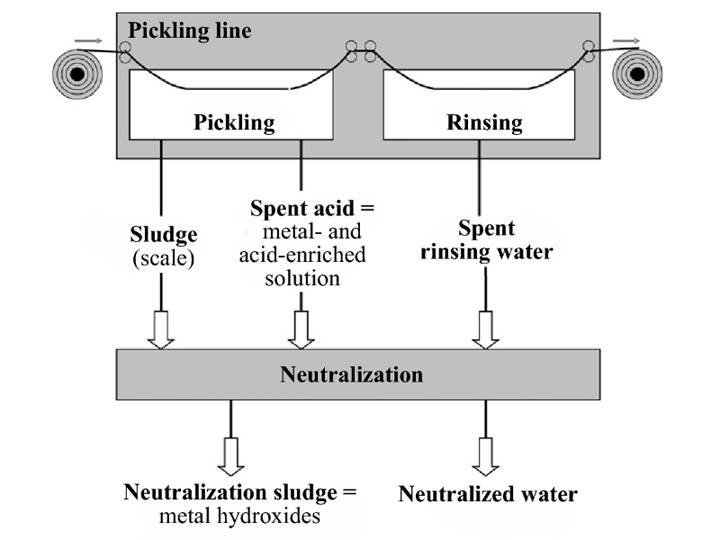

Environmental Pollution

Cov pa phem tseem ceeb hauv cov txheej txheem tsim khoom yog kev ntxuav cov dej khib nyiab uas tsim los ntawm cov txheej txheem ntxuav dej ntawm txhua theem, cov plua plav uas tsim los ntawm cov txheej txheem sandblasting, hydrogen chloride acid pos huab ua los ntawm cov txheej txheem pickling, thiab cov pov tseg uas tsim los ntawm pickling, yaug, phosphating, neutralization thiab tiv thaiv xeb txheej txheem.Tank kua, pov tseg residue, pov tseg lim caij, raw cov khoom khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob

Laser ntxuav

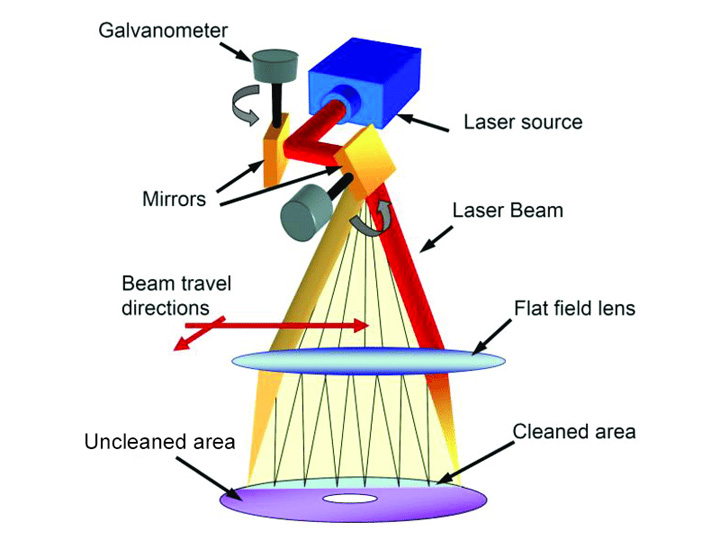

Txoj Cai Ntxuav

Laser ntxuav tshuabyog siv lub zog laser los nkag rau saum npoo ntawm cov khoom.Cov khoom siv hluav taws xob hauv cov khoom nqus lub zog vibration rau li 100 femtoseconds, thiab tsim cov ntshav rau ntawm cov khoom.Tom qab 7-10 picoseconds, lub zog hluav taws xob hloov mus rau hauv lub lattice thiab cov lattice pib vibrate.Tom qab picosecond, cov khoom pib tsim qhov kub thiab txias, thiab cov khoom siv hauv zos irradiated los ntawm lub laser pib ua kom sov, yaj thiab vaporize, thiaj li ua tiav lub hom phiaj ntawm kev ntxuav.

Cov txheej txheem ntxuav & cuam tshuam

Piv nrog rau txoj kev pickling, lub laser tu tshuab yog yooj yim heev, tsis muaj pretreatment yog yuav tsum tau, thiab kev tu cov roj tshem tawm, oxide txheej tshem tawm thiab xeb tshem tawm yuav nqa tawm tib lub sij hawm.Tsuas yog qhib lub cuab yeej kom tso lub teeb tawm, tom qab ntawd ntxuav nws.

Laser tu system tuaj yeem ncav cuag qhov siab tshaj plaws kev lag luam tu theem ntawm Sa3, yuav luag tsis muaj kev puas tsuaj rau lub hardness, hydrophilicity thiab hydrophobicity ntawm cov khoom nto.Nws yog nruj dua li pickling.

Pros thiab Cons

Cov txheej txheem ntws thiab kev ua haujlwm yuav tsum tau ua

Piv nrog rau cov cuab yeej pickling nrog ntau tshaj li kaum ob txheej txheem, laser ntxuav tau ua tiav cov txheej txheem yooj yim tshaj plaws thiab ua tiav ib kauj ruam.Zoo heev shortens tu lub sij hawm thiab cov khoom poob.

Txoj kev pickling muaj cov kev cai nruj ntawm cov txheej txheem kev ua haujlwm: lub workpiece yuav tsum tau degreasing kom ntseeg tau qhov zoo ntawm xeb tshem tawm;cov concentration ntawm cov tshuaj pickling yog tswj los tiv thaiv lub workpiece los ntawm corroded vim acid concentration ntau dhau;Qhov ntsuas kub yog tswj raws li cov txheej txheem tshwj xeeb kom tsis txhob muaj kev puas tsuaj rau lub workpiece thiab cov khoom ua rau corrosion;lub tank pickling maj mam tso cov sludge, uas thaiv cov yeeb nkab cua sov thiab lwm yam khoom siv tswj, thiab yuav tsum tau muab tshem tawm tsis tu ncua;Tsis tas li ntawd, nws yog ib qho tsim nyog yuav tsum tau them sai sai rau lub sijhawm pickling, kev txhaj tshuaj siab, kev ua haujlwm sputtering, cov khoom tso tawm, thiab lwm yam.

Laser tu tuaj yeem paub txog kev ua haujlwm zoo li neeg ruam lossis txawm tias tsis siv neeg tsis siv neeg ua haujlwm tom qab teeb tsa tsis tau nyob rau theem pib.

Cov nyhuv ntxuav thiab ib puag ncig muaj kuab paug

Ntxiv rau qhov muaj zog tu cov nyhuv, laser tu system kuj muaj qhov zoo ntawm kev ua txhaum ntau dua.

Oxygen macular, redness thiab blackening feem ntau tshwm sim vim kev ua yuam kev hauv kev ua haujlwm ntawm txoj kev pickling, thiab qhov kev tsis lees paub yog siab.

Cov dej poob laser kev sim ua pov thawj tias txawm tias lub laser tu yog supersaturated, nws tseem muaj lub zog hlau nplaum, thiab tsis tsim hydroxide thiab lwm yam kuab paug, uas yuav tsis cuam tshuam rau cov txheej txheem tom ntej xws li vuam.

Yuav tsis muaj kev ua qias tuaj ib puag ncig xws li cov kua khib nyiab thiab cov slag nyob rau hauv tag nrho cov txheej txheem ntawm laser tu, uas yog txoj kev tu ntsuab tshaj plaws.

Unit nqi VS Conversion nqi

Cov cuab yeej pickling yuav tsum tau siv tshuaj raws li consumables, yog li cov nqi tsev muaj xws li cov khoom depreciation + consumables nqi.

Laser ntxuav tshuab yuav tsum tsis muaj consumables lwm yam tshaj li yuav khoom.Tus nqi tsev yog qhov depreciation ntawm cov khoom siv.

Yog li ntawd, qhov loj dua qhov tu nplai thiab lub xyoo ntev dua, qhov qis dua cov nqi ntawm laser tu.

Cov kab sib xyaw ntawm cov kab ntau lawm yuav tsum muaj cov txheej txheem nyuaj, thiab qhov sib piv ntawm cov neeg sawv cev ntawm cov khoom siv hlau sib txawv tsis zoo ib yam, yog li cov kab ntau lawm hloov dua siab tshiab yuav tsum muaj tus nqi hloov pauv loj, thiab cov khoom siv hlau yuav tsum tau ntxuav hauv lub sijhawm luv luv. yog ib leeg thiab tsis tuaj yeem hloov pauv tau yooj yim.

Tsis muaj kev hloov pauv tus nqi rau kev tu laser: tom qab hloov cov software tsis tau ntawm tib lub tshuab ntxuav, cov nyhuv ntawm kev ntxuav cov phaj steel ib feeb thiab cov aluminium alloy tom ntej no tuaj yeem ua tiav.Nws yog qhov yooj yim rau cov lag luam los siv JIT saj zawg zog ntau lawm.

Cov ntsiab lus

Pickling phaj muaj ntau yam thiab qhov tob hauv kev tsim khoom, thiab ua lub luag haujlwm zoo hauv kev txhawb nqa kev lag luam.Txawm li cas los xij, nrog kev txhim kho txuas ntxiv ntawm kev tsim khoom lag luam, kev ua kom muaj peev xwm ua kom zoo dua qub thiab kev hloov kho cov qauv kuj tau ua qeeb.

Nrog rau kev txhim kho ntawm tib neeg txoj kev paub txog ib puag ncig, tsoomfwv thiab cov tuam txhab lag luam muaj cov kev cai nruj ntxiv rau cov kab ntau lawm, thiab cov nyiaj tau los ntawm cov lag luam muaj feem cuam tshuam tau thinner thiab thinner.Tag nrho ib puag ncig zoo dua rau kev ntxuav laser.

Tej zaum nyob rau hauv kaum xyoo tom ntej, cov nplooj ntawv pickling yuav muaj lub npe tshiab - laser ntxuav nplooj.